The Indispensable Role of Polycarbonate Solid Sheets in Equipment Protection

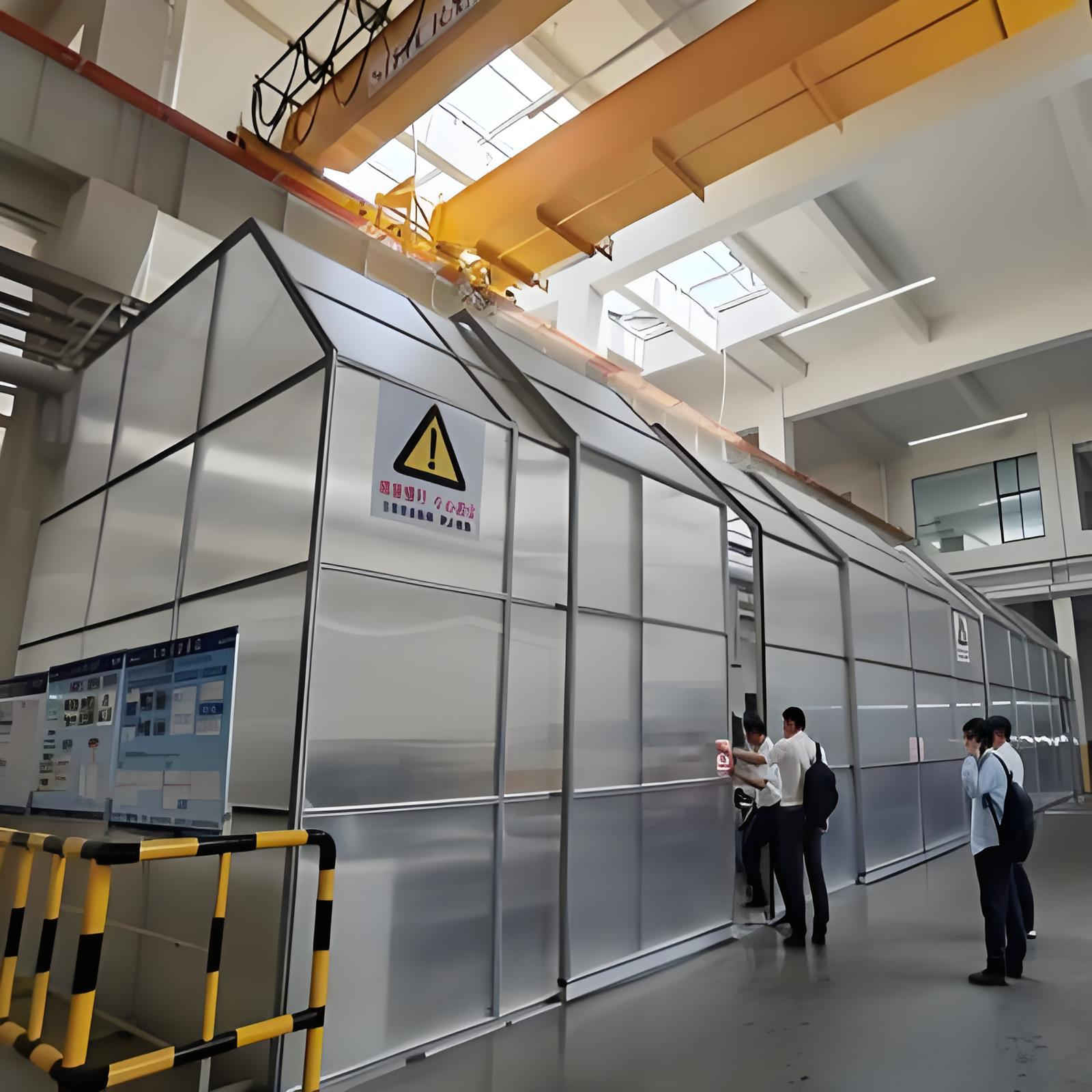

In the dynamic world of industrial operations, the safety and proper functioning of machinery are of utmost importance. One crucial element that plays a significant role in safeguarding these machines is the use of high – quality protective materials. Among them, polycarbonate solid sheets, commonly known as polycarbonate solid endurance sheets, have emerged as a top – choice solution for creating effective equipment protective covers.

Understanding the Need for Equipment Protection

Machines in industrial settings are constantly exposed to various risks. Debris, dust, and other foreign objects can easily find their way into the delicate components of machinery, leading to malfunctions, reduced efficiency, and costly repairs. Moreover, the potential for accidental injuries to operators due to moving parts or flying debris is a serious concern. This is where the importance of a reliable protective device comes into play.

How Polycarbonate Solid Sheets Excel as Equipment Protective Covers

- Superior Impact Resistance

Polycarbonate solid sheets are renowned for their exceptional impact resistance. They can withstand high – velocity impacts from flying objects without shattering. This property makes them ideal for protecting machinery from any potential collisions with tools, parts, or other debris that might be present in the industrial environment. For example, in a manufacturing plant where heavy – duty machinery is in operation, there is always a risk of small metal parts being ejected during the production process. A polycarbonate solid sheet – based protective cover can effectively intercept these parts, preventing them from causing damage to the machine or harming nearby workers.

- Dust and Debris Barrier

These sheets act as an excellent barrier against dust and debris. In industrial facilities, dust particles can accumulate inside machinery over time, clogging filters, bearings, and other critical components. By enclosing the machine with a polycarbonate solid sheet protective cover, the ingress of dust and debris is significantly reduced. This not only helps to maintain the cleanliness of the machine but also extends its lifespan by preventing premature wear and tear caused by the abrasive action of dust particles.

- Transparency for Visual Monitoring

One of the unique advantages of polycarbonate solid sheets is their high transparency. This allows operators to visually monitor the operation of the machinery without having to remove the protective cover. In processes where it is crucial to keep an eye on the machinery’s performance, such as in precision manufacturing or assembly lines, the transparency of the polycarbonate sheet enables real – time inspection. This helps in quickly detecting any irregularities, such as unusual vibrations or abnormal material flow, and taking immediate corrective actions.

- Customizability

Polycarbonate solid sheets can be easily fabricated and customized to fit the specific shape and size requirements of different machinery. Whether it is a large – scale industrial machine or a small, specialized piece of equipment, the sheets can be cut, bent, and assembled to create a perfect – fitting protective cover. This flexibility in customization ensures that every machine can be provided with the most appropriate level of protection.

Real – World Applications

- Automotive Manufacturing: In automotive assembly plants, polycarbonate solid sheet protective covers are used to protect robotic arms and other automated machinery. These sheets prevent any loose parts or tools from interfering with the operation of the robots, ensuring smooth and accurate assembly processes.

- Food and Beverage Industry: In food and beverage production facilities, maintaining a clean and hygienic environment is essential. Polycarbonate solid sheet protective covers not only protect the processing equipment from dust and debris but also meet the strict hygiene standards of the industry. Their smooth surface is easy to clean and sanitize, preventing the growth of bacteria and other contaminants.

- Metalworking Factories: In metalworking factories, where high – speed cutting and grinding operations are common, polycarbonate solid sheet protective covers shield the machinery from sparks, metal chips, and other flying debris. This protects both the equipment and the workers in the vicinity, reducing the risk of accidents and equipment damage.

In conclusion, polycarbonate solid sheets have proven to be an invaluable asset in the realm of equipment protection. Their combination of impact resistance, dust – proof capabilities, transparency, and customizability makes them the go – to choice for creating effective machinery protective covers. By investing in polycarbonate solid sheet – based protective devices, industries can enhance the safety, efficiency, and longevity of their valuable machinery, ultimately leading to more productive and sustainable operations.