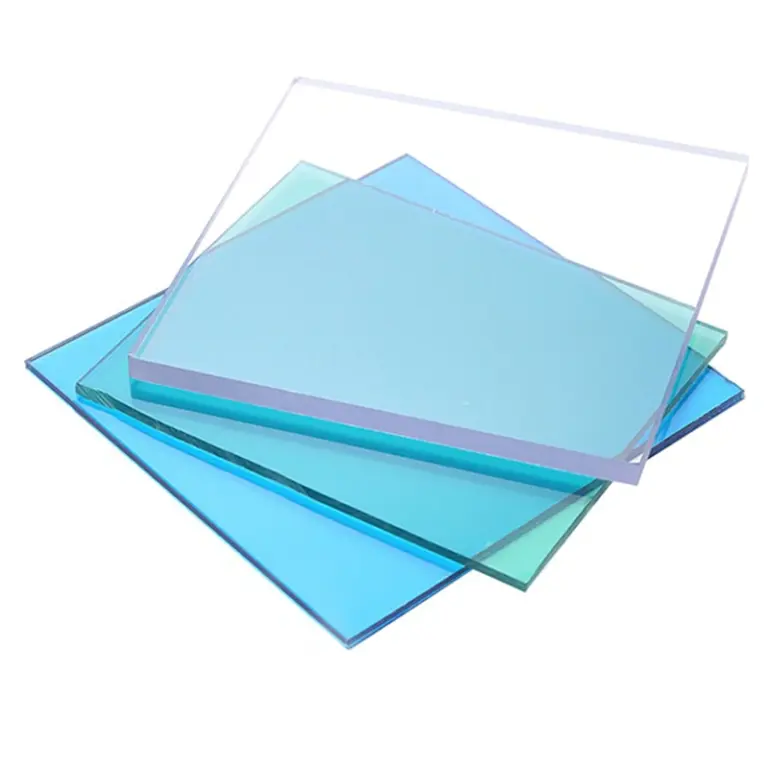

| Name | Solid Polycarbonate Sheet |

| Raw material | 100% bayer material or sabic material or customized |

| Color | Clear, Opal ,Blue,Lake Blue,Green,Bronze, or Customized |

| Certificate | ISO9001、SGS、Test Report |

| Thickness | 1.1-20mm or Customized |

| Width | 1.22m、1.56m、1.82m、2.10m, The maximum width can be made 2.1 m special width, large quantity can be customized |

| length | 2.44m or custom-made, 30m or 60m is a coil, the thickness of the coil is 4.5mm or less, and more than 5mm is a flat plate. The common specification of the flat plate is: 1.22m*2.44m |

| Warranty | 10-Year |

| Surface | UV protection, Anti-fog,Anti-static,hardening,fire retandant,etc. |

| Samples | Free samples will send you for test |

| Application | Riot shields, Submarine covers, Tunnel protection, Noise barriers, special machinery covers, Greenhouses, Carports, Skylights |

| Type | Flat polycarbonate sheet |

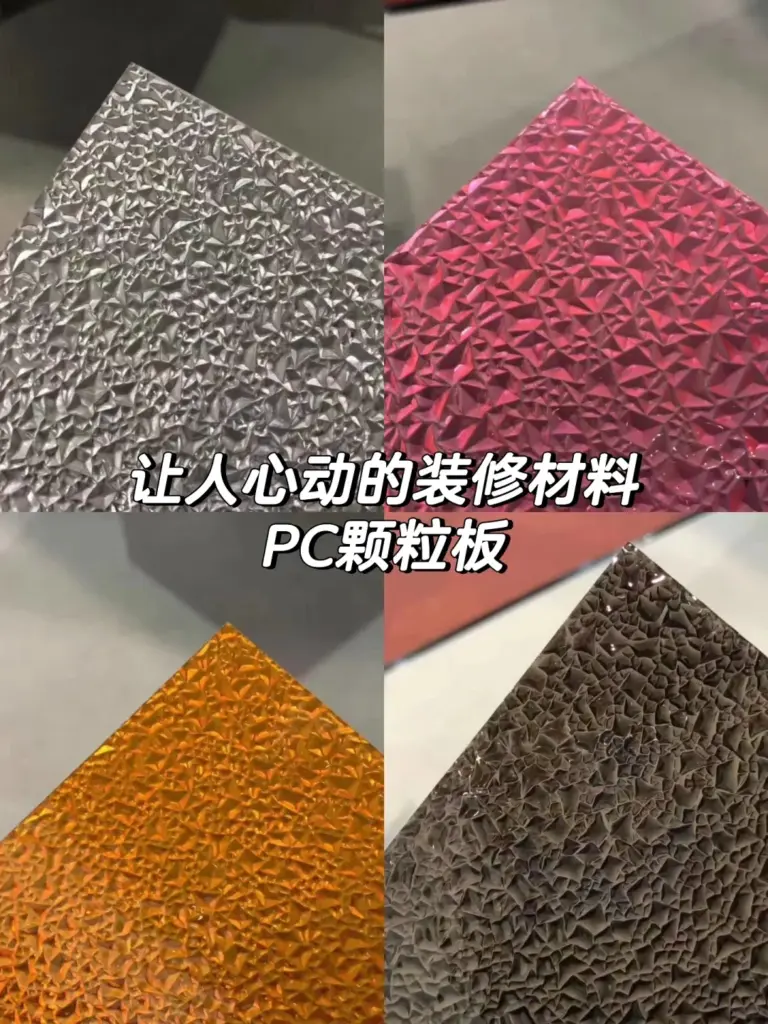

| Embossed polycarbonate sheet | |

| Anti-fog polycarbonate sheet | |

| Colourful polycarbonate sheet | |

| Partition sheet | |

| Light Diffuser sheet |

Solid Polycarbonate Sheet

- Product Name : Solid polycarbonate sheet

- Thickness : 0.8mm – 22mm

- Width : Max 2100mm

- length :Customizee

- Standard Size : 1220 * 2440mm / 4′ * 8′

- MOQ : 100 square meters

Product Details

| Light Transmission | Depending on the color, the transmittance can be up to 0-89%. | |

| Energy saving | Low heat transfer coefficient (K value), good thermal insulation, energy saving is 1.5-1.7 times of the same thickness of glass. | |

| Light | The weight is 1/15 of the same thickness of glass. | |

| Impact Strength | Good toughness, not easy to be damaged in transportation, installation and use;Its impact strength is 250 times that of glass and 30 times that of plexiglass. | |

| Resistance to aging | The surface of the product contains a UV-resistant coextruded layer, outdoor weather resistance is good, long-term use still maintain good optical properties and mechanical properties | |

| Resistance to wind pressure | Wind pressure performance up to the national standard GB/T 7106-2008 level 1. | |

| Large temperature difference | Long-term use temperature: -40c to 120C. | |

| Effect of Soundproof | Polycarbonate with hollow structure has good sound insulation and can effectively reduce noise. | |

| Flame retardant | According to the national standard gb8624-2012 is class B1 flammable. | |

| Easy to install | The minimum bending radius is 175 times the thickness of the plate. | |

| Features | Unit | Date |

| Specific Gravity | g/cm² | 1.2 |

| LightTransmission | % | 0~88 |

| lmpactStrength | J/m | 850 |

| The Bending Strength | N/mm² | 100 |

| Tensile Strength | N/mm² | >=60 |

| Modulus of Elasticity | M pa | 2400 |

| Tensile Stressat Break | M pa | >=65 |

| Elongation at Break | % | >100 |

| Specific Heat | KJ/KG·K | 1.17 |

| Heat Conductivity | W/m²·K | 0.2 |

| Heat Deflection Temperature | °C | 140 |

| Coefficient of Thermal Expansion | mm/m·°C | 0.067 |

| Range of Temperature | °C | -40~+120 |

| Effect of Soundproof | 10mm PC sheet | Attenuation 33 DB |

Solid polycarbonate sheets are an innovative material that has garnered considerable attention in the construction and industrial sectors due to their outstanding characteristics and wide range of applications. These polycarbonate panels not only possess excellent transparency and thermal insulation, but also have remarkable impact resistance, corrosion resistance, wind pressure resistance, temperature resistance, sound insulation performance, and flame retardancy, all while being lightweight. Their multifunctional properties make them an ideal choice for various fields, including construction, industrial protection, public spaces, and agriculture.

Transparency of solid polycarbonate sheets. This material effectively transmits light, filling indoor spaces with natural brightness. It not only reduces the need for artificial lighting but also enhances the comfort and visual effects within the building.

Thermal insulation of solid polycarbonate sheets. They exhibit exceptional thermal insulation performance, effectively preventing the impact of high and low outdoor temperatures on the indoor environment. During hot summers, they can block solar radiation and heat, creating a cool and comfortable indoor environment. In cold winters, they help retain indoor heat, providing good insulation.

Impact resistance of solid polycarbonate sheets. Compared to glass, solid polycarbonate panels are more resistant to impact and possess outstanding corrosion resistance and wind pressure resistance, capable of withstanding various chemicals and weather conditions. This makes them an ideal choice for locations exposed to harsh weather and external forces, such as rest areas in stations, airports, ports, and tunnel entrances.

Temperature resistance of solid polycarbonate sheets. In extreme temperature changes, solid polycarbonate panels maintain their stability and strength without significant expansion or contraction due to temperature variations. This makes them highly suitable for areas with fluctuating climate conditions.

Sound insulation of solid polycarbonate sheets. They provide effective sound insulation, reducing the interference of external noise. This makes solid polycarbonate panels an ideal choice for places such as sports stadiums, amusement parks, and public parks that require noise control.

Flame retardancy of solid polycarbonate sheets. They effectively prevent the spread of fires, providing additional safety assurance in the construction and industrial sectors.

Lightweight nature of solid polycarbonate sheets. They also have extensive applications in architectural decoration and interior partitions. Not only are they convenient to install and transport, but they also reduce the weight of buildings, thus minimizing the load on the structures.

In conclusion, Songxia solid polycarbonate sheets are widely applied in construction, industrial protection, factory lighting and rainproof canopies, as well as in rest areas of stations, airports, ports, and tunnel entrances, thanks to their exceptional characteristics such as transparency, thermal insulation, impact resistance, corrosion resistance, wind pressure resistance, temperature resistance, sound insulation performance, and flame retardancy.

Polycarbonate skylight roofs – Lightweight and energy-efficient

Polycarbonate panels outperform other plastic roofing materials in terms of strength, stability, and durability, making them the ideal choice for skylight roofs and covers in buildings. They offer UV resistance, waterproofing capabilities, and a lightweight design, resulting in lower transportation and handling costs. Polycarbonate’s exceptional thermal insulation performance plays a crucial role in daylight architecture, providing warmth during winter and coolness during summer. Polycarbonate daylighting contributes significantly to energy conservation and sustainable development.

Acoustic Highway with Solid Polycarbonate Sheets

Solid polycarbonate sheets, manufactured through co-extrusion, possess high sound insulation and transparency, making them suitable for highway barriers. It is understood that the noise level on highways typically ranges from 70 decibels to 80 decibels. Solid polycarbonate significantly reduces noise in highway areas, achieving a noticeable reduction of up to 32 decibels. Furthermore, it is sturdy and has high impact strength. Transparent polycarbonate offers excellent visibility and an elegant appearance. UV-resistant and soundproof, polycarbonate barriers do not yellow or become brittle, providing a lifespan of 10-20 years.

How thick should I use solid polycarbonate for a home roof

For residential roofing projects, the thickness of solid polycarbonate panels typically ranges from 2mm to 20mm. If you are planning to replace a canopy roof, we recommend using a thickness of 2mm to 8mm to ensure sufficient security. A 4mm solid polycarbonate sheet is suitable for patio covers and pergolas. If the polycarbonate has a sturdy frame support, a thickness of 5mm is sufficient, and there are various standard sizes available for residential roof applications.

1.High Quality: with advanced producing equipment and strong QC team.

2.High Supply Ability: with 8 producing lines and output of 50,000 tons per year.

3.Rich Experience: with more than 20 years experience.

4.Nice Service: quick reply and warm service to meet your needs.

5.Quality Assurance: 5-10 years.

6.impact resistance, bendable, high transmittance, difficult to burn, light-weight, nice sound insulation, anti-drip, anti-ultraviolet light, energy saving, environmental protection, etc.