Common Deep Processing Techniques for PC Sheets Polycarbonate

(PC) sheets have gained widespread popularity across various industries due to their exceptional properties such as high impact resistance, transparency, and versatility. To meet diverse application requirements, PC sheets often undergo a range of deep processing techniques. In this article, we’ll explore the most common ones.

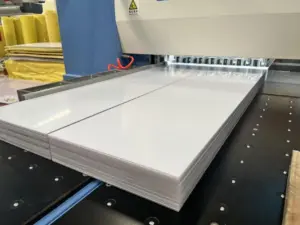

- Cutting Cutting is the fundamental process in PC sheet fabrication. It can be done manually using serrated saws, or with equipment like circular saws, vibrating knives, and laser cutters. Among these, laser cutting stands out for its high precision, enabling the creation of complex patterns with remarkable accuracy.

- Engraving Engraving on PC sheets is primarily done through two methods: laser engraving and drill engraving. Drill engraving is more commonly used, allowing for shape engraving, hole drilling, and font engraving on PC sheets. The equipment can achieve a precision of within 0.07mm, ensuring intricate and detailed results.

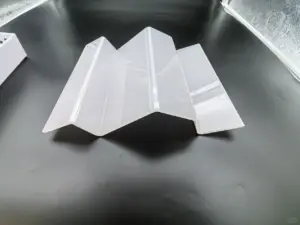

- Bending Bending of PC sheets can be performed using either cold bending or hot bending techniques. Cold bending is typically carried out at room temperature and is suitable for thin sheets with a thickness of ≤3mm. Hot bending, on the other hand, involves heating the PC sheet to 150-160℃ to soften it before bending, making it ideal forthicker sheets.

- Polishing Polishing is a surface treatment process mainly applied to PC sheets after cutting and engraving. Tools such as utility knives and wool pads are used to enhance the smoothness of the PC sheet surface, resulting in a more refined and professional finish.

- Bonding Bonding involves using specialized adhesives to join PC sheets together. This technique is widely used in the production of various boxes, mechanical components, and crafts, with the requirement that the joints are flat and smooth for both aesthetic and functional purposes.

- Thermoforming In thermoforming, PC sheets are heated until soft and then placed into a mold to cool and take shape. This process allows for the creation of products with complex shapes such as domes and curved surfaces. It’s crucial to control the time and temperature accurately to avoid internal bubbling.

- Vacuum Forming Vacuum forming involves heating a flat PC sheet until it becomes soft, then using vacuum pressure to draw it onto the surface of a mold where it cools and solidifies. This versatile technique is suitable for deep processing of various PC sheets and can produce packaging products of different shapes.

These deep processing techniques enable PC sheets to be transformed into a wide array of products, catering to the needs of industries such as construction, automotive, electronics, and more. By choosing the appropriate processing method, manufacturers can unlock the full potential of PC sheets and create high-quality, customized products.