When we talk about construction materials, identifying the best polycarbonate sheets is challenging because we have to look for both durability and performance. These sheets have become integral components in architectural projects worldwide, offering a harmonious blend of strength and visual appeal. Whether you are a supplier investigating top-tier products or a business owner aiming to enhance your offerings, this guide will help you navigate the best and most economical sheets.

From understanding the diverse applications to discerning the critical differences between various options, this guide aims to equip you with the knowledge needed to make informed decisions for your clients.

Let’s start with the basics, which are crucial to picking the right material to expand your business.

What is polycarbonate?

Let’s start by looking into the basics of our topic, “polycarbonate.” As per the Oxford Dictionary, it is articulated as “A synthetic resin in which the polymer units are linked through carbonate groups, including various molding materials and films.” Simply put, polycarbonates stand out as robust, rigid, hard, and transparent engineering thermoplastics, celebrated for their moldability, durability, and lightweight attributes, making them a universal choice in engineering applications.

The inception of polycarbonate dates back to 1898 when German scientist Alfred Einhorn, situated at the University of Munich, uncovered its potential. Despite the discovery, commercialization did not take root until the 1950s.

But now polycarbonate roof sheets have revolutionized the world, so this market is flourishing. As outlined by ADS reports’ global forecast, the market witnessed a valuation of USD 1.61 billion in 2017, with a projected escalation to USD 2.11 billion by 2023, demonstrating a compound annual growth rate of 4.5%. This growth is intricately tied to the ascendancy of polycarbonate roofing, progressively superseding traditional materials like glass and acrylic. The rationale behind this shift lies in the easy installation, durability, light transmittance, insulation efficacy, aesthetic appeal, and the availability of diverse variants these sheets offer.

What are the Uses of Polycarbonate Sheets?

Designed with UV protection and weather resistance, they offer a versatile solution suitable for indoor and outdoor applications, meeting the demands of commercial ventures and DIY projects. This resilient material is preferred among manufacturers for various applications, notably in producing CDs, DVDs, mobile devices, and laptops.

Our solid polycarbonate sheeting takes the lead, especially in the roofing industry and outdoor applications. Its enduring high quality ensures longevity, making it virtually unbreakable and a reliable choice that lasts year after year. Some common applications of polycarbonate are listed below:

- Construction

- Conservatory roofs

- Greenhouse roofing

- Canopy roofs

- Components for aircraft and automotive

- Glazing

- Lighting

- Protective sneeze guards

- Machine guards

- Security components

- Skylights

- Signage

Q: What is the difference between polycarbonate plexiglass sheets?

Distinguishing between polycarbonate and plexiglass sheets can be a common challenge for many. It’s crucial to acquaint yourself with the distinctive properties of both before making a decision. Let’s explore the primary differences:

Safety Factors

Polycarbonates exhibit a low risk of catching fire and are capable of self-extinguishing in case of a fire outbreak. Meanwhile, plexiglass displays high flammability, burning rapidly in the event of a fire.

Rigidity

Polycarbonate demonstrates superior rigidity and strength, withstanding high temperatures effectively, while Plexiglass is prone to cracking and breaking and not as resilient to high heat as polycarbonate sheets.

What are the differences between polycarbonate sheets and acrylic sheets?

Understanding the disparities between polycarbonate and acrylic is crucial when selecting the right material for your needs. Here’s a breakdown of the key differences:

Impact Strength

Polycarbonate has an impressive 30 times the impact strength of standard acrylic sheets and over 250 times that of glass with equivalent thickness. This exceptional strength makes polycarbonate a preferred choice compared to other plastic forms.

Weight and Cost

Polycarbonate is heavier than acrylic plastic, and while it may be slightly more expensive, the investment is justified by its unparalleled durability. On the other hand, acrylic is lightweight but tends to be less robust than polycarbonate.

Types of Polycarbonate Roof Systems

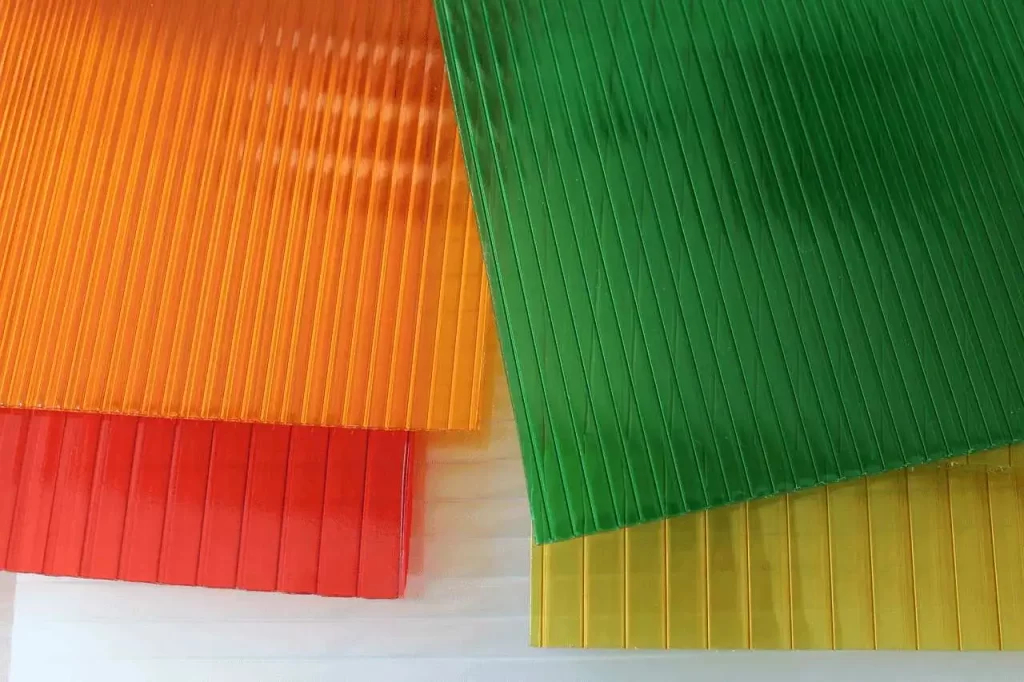

When it comes to roofing in construction, polycarbonate sheeting offers diverse solutions, presenting itself in various configurations. Here’s a breakdown of the different types:

Twin-Wall and Multiwall Polycarbonate Sheets

Commonly used in conservatories and lean-to roofs, this versatile material finds its ideal applications in various settings. These sheets are well-suited for conservatories, canopies, vertical glazing, displays, roof lights, signage, walkways, swimming pool covers, insulation, and more.

Solid Polycarbonate Sheets

Solid sheets are characterized by substantial thickness; our polycarbonate sheets ensure a robust, virtually indestructible roofing system. These sheets have diverse applications in protective screens, vertical glazing, bus shelters, doors, train windows, and riot shields. Transparent like glass and UV-protected on both faces, they are suitable for skylights, helmets, security glazing, railings, balconies, and more.

Corrugated Polycarbonate Sheets

Our corrugated polycarbonate sheets offer flexibility, easily bending or folding to meet your design preferences. Installation is a breeze – they can be layered on other sheets, streamlining the fitting process. Versatile in applications, these sheets find use in conservatories, signage, roofing, glazing, DIY projects, swimming pools, greenhouses, and beyond.

Top of Form

How to Connect with Us?

Ready to elevate your roofing solutions with Songxia? Explore our extensive polycarbonate sheets on our dedicated page, offering options for various budgets and project requirements. As an approved polycarbonate roofing supplier, our Songxia team is here to assist you every step of the way. Don’t hesitate to reach out if you are uncertain about the best polycarbonate sheets for your budget or project. Connect with us today at +86.137.5151.9696 via WhatsApp or email us at [email protected].

FAQs

Q: Can I quickly Cut Polycarbonate Sheets?

A: Absolutely! Usually provided in convenient sheet form, these sheets are quite user-friendly for cutting. A utility knife does the trick for thinner sheets – just score and snap.

Q: Is Polycarbonate Cost-Effective?

A: Wondering about the price tag? Polycarbonate proves to be a cost-effective choice compared to materials like glass. It is lighter, and its flexibility and resilience make it easier to work with.

Q: What’s the Lifespan of Polycarbonate Panels?

A: Polycarbonate panels typically boast an average lifespan ranging from 10 to 20 years, and with proper care, they might even surpass these expectations. This extended durability ensures that you get excellent value for your investment.

Is Polycarbonate Resistant to Heat?

A: Yes, unlike glass, polycarbonate shows an impressive resistance to extreme temperatures, enhancing its safety for use in both construction and household items. Remarkably, polycarbonate can endure temperatures of around 270 degrees for extended periods or sudden bursts of heat up to 1166 degrees without any signs of distortion, breakage, or heat absorption.

Q: Which Clear Roofing Material Reigns Supreme?

A: The robust thermoplastic material of polycarbonate is lightweight and resilient against both low and high temperatures. Its durability and practicality make polycarbonate ideal for various applications, including greenhouses, patios, and deck areas.