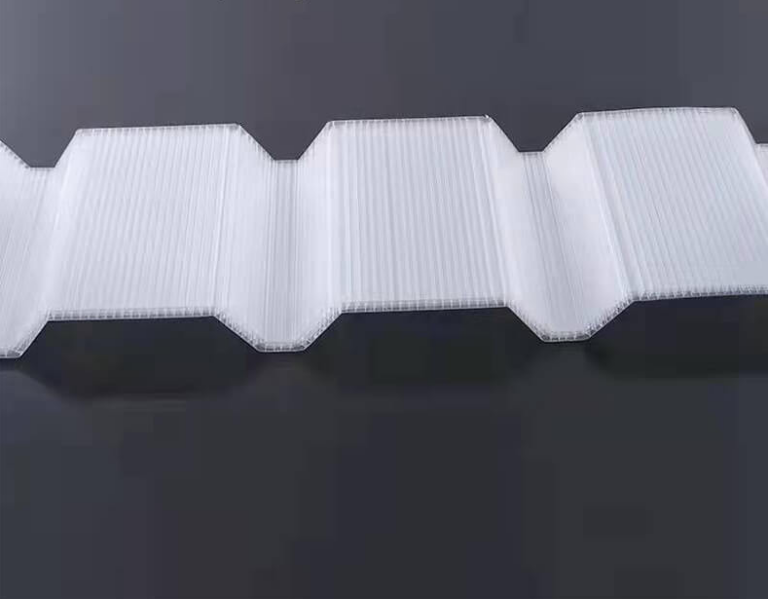

4-layer Hollow Polycarbonate Corrugated Sheet

| Specification | |

|---|---|

| Product Name | 4-Layer Hollow PC Corrugated Sheet |

| Thickness | 6 mm / 8 mm / 10 mm / 12 mm / 14 mm / 16 mm |

| Colours | Lake Blue · Royal Blue · Brown · Milky · Grass Green · Clear · Custom |

| Width | Custom (≤ 2.1 m) |

| Length | Custom |

| Surface | 50 µm UV coat |

| Fire Class | B1 |

| U-value | 3.0 W/m²·K |

| Light Transmission | 65 % ± 5 % |

Product Description

4-layer hollow polycarbonate corrugated sheet is a type of building material made from polycarbonate plastic. It consists of four layers of polycarbonate material arranged in a hollow, corrugated structure. These sheets are commonly used in construction for roofing, skylights, and other applications where lightweight, durable, and translucent materials are required. The corrugated design provides strength while also allowing for flexibility and easy installation. Additionally, the multi-layer structure enhances insulation properties, making it suitable for regulating temperature and reducing energy costs. Overall, 4-layer hollow polycarbonate corrugated sheets offer a combination of strength, versatility, and thermal performance, making them popular choices in various construction projects.

Product Advantages

- High daylight: Up to 75 % light transmission with a UV cap that keeps clarity for ten years.

- UV shield: One side has a co-extruded UV layer that blocks harmful rays and protects displays or crops.

- Low weight: About half the density of glass, cutting transport, handling, and frame cost.

- Fire safety: Meets GB 8624-2012 class B1; self-extinguishes and gives off no toxic smoke.

- Sound control: At equal thickness the panel reduces noise 5-9 dB more than glass.

- Thermal saving: The multi-wall core lowers heat flow; energy loss is 7 – 25 % lower than glass of the same thickness.

- Wide temperature range: Keeps mechanical strength from -40 °C to +120 °C.

- Weather resistance: Physical properties stay stable in outdoor conditions year-round.

- Flexible installation: Cold-bend on site to a radius ≥ 175 × sheet thickness, or hot-form for tighter curves.

Product Application

- Daylighting roofs for sports halls, pools, and gyms

- Roof glazing at rail stations and airports

- Factory skylights, awnings, façade panels, and partitions

- Carports, domes, and walkway covers in private or retail buildings

- Municipal canopies over bridges and corridors

- Agricultural greenhouses and large-scale livestock shelters