| Name | Multi walls Polycarbonate Hollow Sheet |

| Raw material | 100% bayer material or sabic material or customized |

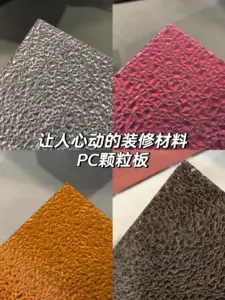

| Color | Transparent, milky white, lake blue, grass green, brown or customized |

| Certificate | ISO9001、SGS、Test Report |

| Thickness | 6-20mm or Customized |

| Width | 1.22m、1.56m、1.82m、2.10m, The maximum width can be made 2.1 m special width, large quantity can be customized |

| length | 2.44m or custom-made, the flat plate is: 1.22m*2.44m |

| Warranty | 10-Year |

| Surface | UV protection, Anti-fog,Anti-static,hardening,fire retandant,etc. |

| Samples | Free samples will send you for test |

| Application | Riot shields, Submarine covers, Tunnel protection, Noise barriers, special machinery covers, Greenhouses, Carports, Skylights |

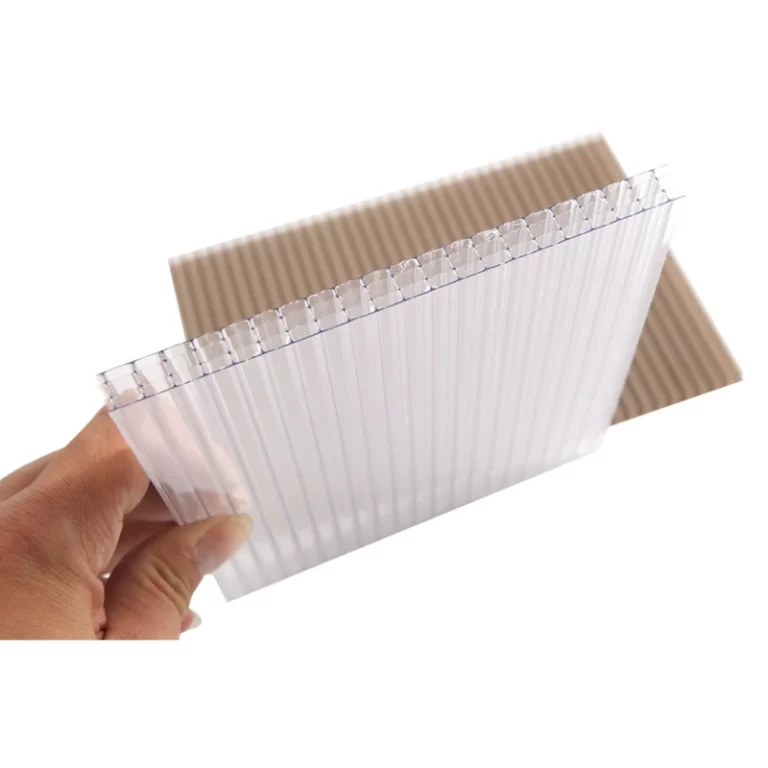

| Type | Twin walls Polycarbonate Sheet |

| Multi-walls Polycarbonate Sheet | |

| Honeycomb Polycarbonate Sheet |

Multi-Wall Polycarbonate Sheets for Performance

- Lightweight and easy to install and operate.

- 80% light transmission and light diffusion.

- Provides insulation and energy savings.

- Durable and safe.

Product Details

| Light Transmission | Depending on the color, the transmittance can be up to 0-89%. | |

| Energy saving | Low heat transfer coefficient (K value), good thermal insulation, energy saving is 1.5-1.7 times of the same thickness of glass. | |

| Light | The weight is 1/15 of the same thickness of glass. | |

| Impact Strength | Good toughness, not easy to be damaged in transportation, installation and use;Its impact strength is 250 times that of glass and 30 times that of plexiglass. | |

| Resistance to aging | The surface of the product contains a UV-resistant coextruded layer, outdoor weather resistance is good, long-term use still maintain good optical properties and mechanical properties | |

| Resistance to wind pressure | Wind pressure performance up to the national standard GB/T 7106-2008 level 1. | |

| Large temperature difference | Long-term use temperature: -40c to 120C. | |

| Effect of Soundproof | Polycarbonate with hollow structure has good sound insulation and can effectively reduce noise. | |

| Flame retardant | According to the national standard gb8624-2012 is class B1 flammable. | |

| Easy to install | The minimum bending radius is 175 times the thickness of the plate. | |

| Features | Unit | Date |

| Specific Gravity | g/cm² | 1.2 |

| LightTransmission | % | 0~88 |

| lmpactStrength | J/m | 850 |

| The Bending Strength | N/mm² | 100 |

| Tensile Strength | N/mm² | >=60 |

| Modulus of Elasticity | M pa | 2400 |

| Tensile Stressat Break | M pa | >=65 |

| Elongation at Break | % | >100 |

| Specific Heat | KJ/KG·K | 1.17 |

| Heat Conductivity | W/m²·K | 0.2 |

| Heat Deflection Temperature | °C | 140 |

| Coefficient of Thermal Expansion | mm/m·°C | 0.067 |

| Range of Temperature | °C | -40~+120 |

| Effect of Soundproof | 10mm PC sheet | Attenuation 33 DB |

Overview

Multi-wall polycarbonate sheets have three or more hollow walls. The extra air chambers raise insulation while keeping the sheet light and tough.

Songxia panels use virgin SABIC LEXAN™ or Covestro MAKROLON® resin with a co-extruded UV layer for long outdoor life.

Thermal Insulation

Multiple air spaces cut heat flow better than twin-wall sheets. Buildings stay warmer in winter and cooler in summer, lowering heating and cooling costs.

Adjustable Thickness & Strength

Standard thicknesses run from 6 mm to 20 mm, and custom gauges are available. Thicker panels give higher stiffness and load capacity for snow, wind, or long spans.

Impact & Weather Resistance

Material toughness is about 250 times that of glass. The UV cap blocks more than 98 % of damaging ultraviolet light, so the sheet will not yellow or become brittle.

Custom Supply

Widths up to 2.1 m, cut-to-length service, and colors such as clear, opal, blue, green, and brown. Surface options include anti-fog, anti-static, hard coat, and fire-retardant grades.

Typical Applications

- Cold-storage walls and roofs

- Greenhouses, livestock shelters, and nursery tunnels

- Skylights, canopies, and carports

- Building façades that need daylight and insulation

- Noise barriers and tunnel cladding

With high insulation, low weight, and strong impact resistance, Songxia multi-wall polycarbonate sheets meet the needs of municipal, residential, and commercial projects that require energy-saving, durable, and good-looking glazing.

Reliable Quality: We use advanced production equipment and a strict quality‑control system.

Large Capacity: Eight production lines give an annual output of 50 000 tons.

Proven Experience: We have more than twenty years of manufacturing and export history.

Responsive Service: Dedicated staff reply quickly and follow each order through delivery.

Warranty: We provide a five‑ to ten‑year product warranty.

Performance: Our sheets offer high impact resistance, good bendability, high light transmission, self‑extinguishing fire performance, low weight, sound insulation, anti‑drip surfaces, UV blocking, energy savings, and recyclability.